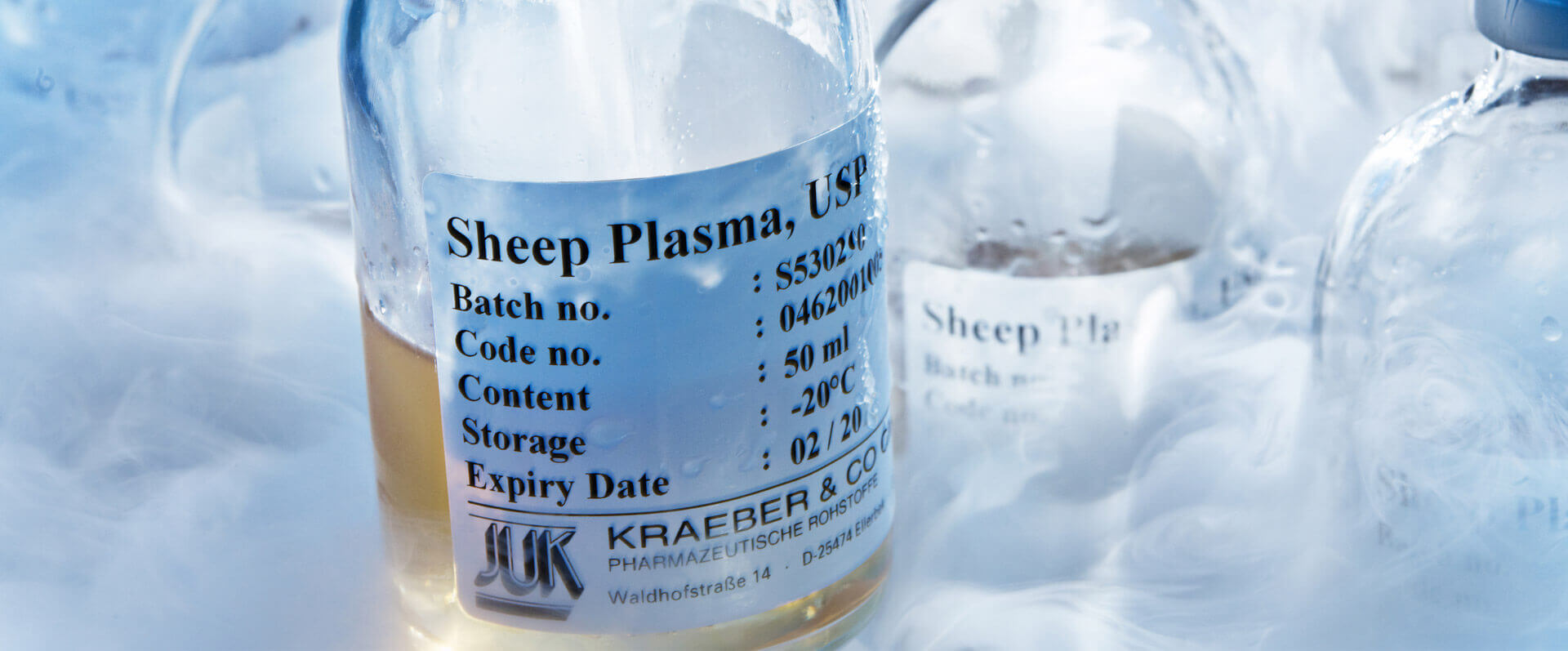

Kraeber & Co GmbH is an independent family business based in Ellerbek on the outskirts of Hamburg, Germany. We sell Active Pharmaceutical Ingredients (APIs), synthetically derived products and biological substances of animal or plant origin. Our department for Bioscience Solutions develops and produces substances for medical devices, diagnostic and laboratory purposes.

The pharmaceutical, cosmetic, food and feed industry is our business area resting upon long-standing expertise combined with profound knowledge of the international markets.

Read More